150ml ~ 1000ml 자동 올리브 오일 식용유 장비, 기계, 오일 충전, 캡핑, 라벨링 및 씰링 기계

설명

기본정보

| 모델 번호. | SD-YTGZJ |

| 자동 메모 | 자동으로 |

| 재료 유형 | 체액 |

| 밸브 헤드 채우기 | 다중 머리 |

| 피드 실린더 구조 | 여러 방에서 먹이주기 |

| 투약 장치 | 축차 |

| 충전 원리 | 압력 |

| 포장용기 리프팅 구조 | 공압 리프팅 |

| 구조 | 선의 |

| 포장 | 병 |

| 포장재 | 플라스틱 |

| 핵심 구성요소 | 모터, 압력용기, 펌프, PLC, 기어박스, 베어링 |

| 운송 패키지 | 나무 박스 |

| 사양 | 수입된 정전기 방지 필름으로 덮여 강화됨 |

| 등록 상표 | 쇼에서 |

| 기원 | 상하이 |

| HS 코드 | 8422301090 |

| 생산 능력 | 1000 |

포장 및 배송

제품 단위당 포장 크기: 180.00cm * 200.00cm * 180.00cm. 제품 단위당 총 중량: 500,000kg상품 설명

150ml ~ 1000ml 자동 올리브 모터 식용유 장비, 기계, 오일 충전, 캡핑, 라벨링, 씰링, 제품 설명

모델 | CGF12125 | CGF18186 | CGF24248 | CGF323210 | CGF404012 | CGF505012 | CGF606015 | CGF808020 | |||

세탁횟수, 헤드 채우기 및 닫기 | 2012년 4월 12일 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-12 | 60-60-15 | 80-80-20 | |||

생산 용량(600ml)(W/H) | 2000- 4000 | 5000- 7000 | 8000- 12000 | 12000- 15000 | 16000- 20000 | 20000- 24000 | 25000- 30000 | 35000- 40000 | |||

어울리는 병 규격(mm) | Φ=50-110 H=170 용량=330-2250ml | ||||||||||

워슈드럭(kg/cm2) | 2~3 | ||||||||||

모터 출력(kW) | 주로 모터 2,2kW | 주로 모터 2,2kW | 주로 모터 3kW | 주로 모터 5,5kW | 주로 모터 7,5kW | 주로 모터 11kW | 주로 모터 15kW | 주로 모터 1 9kW | |||

전체 치수(mm) | 2400× 1650×2500 | 2600× 1920×2550 | 3100× 2300×2800 | 3800× 2800×2900 | 4600× 2800×2900 | 5450× 3300×2900 | 6500× 4500×2900 | 76800× 66400 ×2850 | |||

체중(kg) | 2500 | 3500 | 4500 | 6500 | 8500 | 9800 | 12800 | 15000 | |||

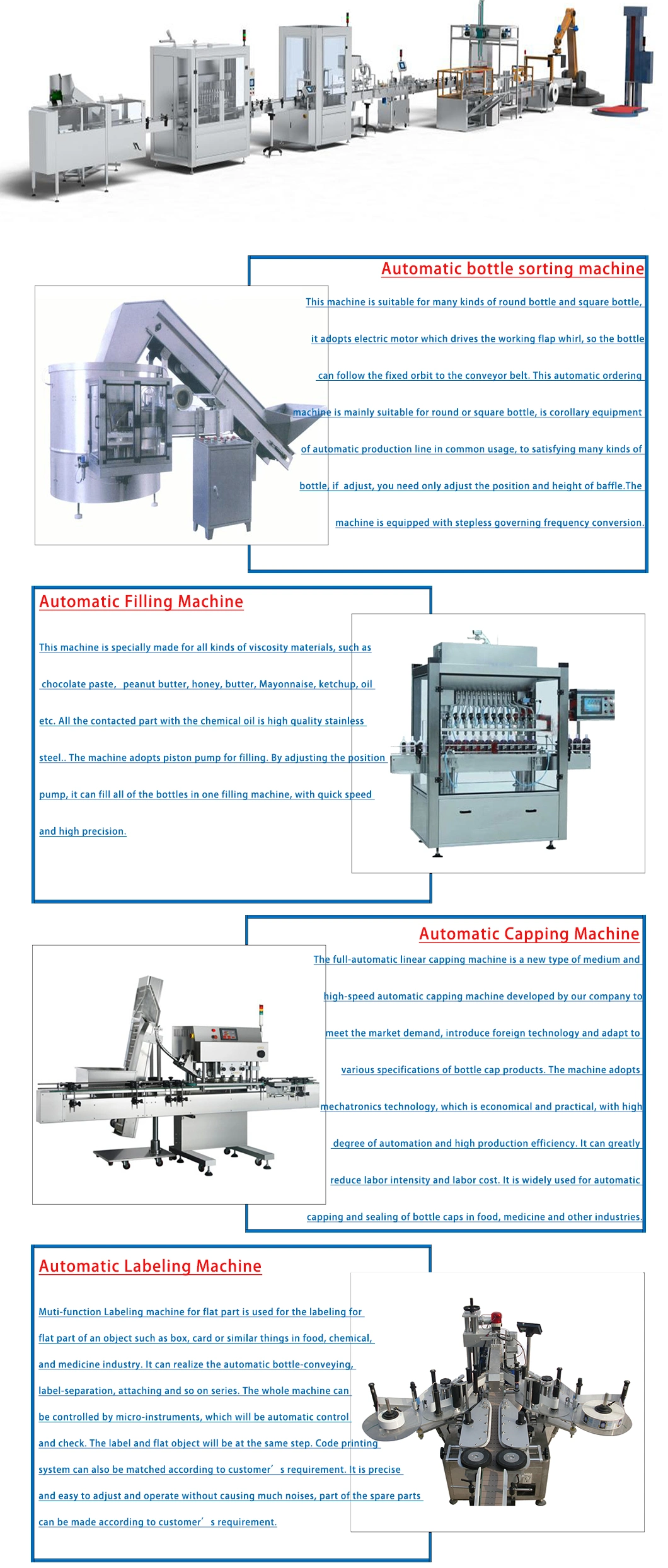

순서도: 병 언스크램블러 - 헹굼-건조 조명 제어 - 체적 액체 충전 기계 - 캡핑 기계 - 라벨링 기계 - 인쇄 - 상자 포장 액체 충전 생산 라인은 액체 충전 기계, 자동 캡핑 기계, 라벨링 기계 등으로 구성됩니다. 간장, 식초, 식물성 기름 및 약제 액체를 채우는. 지능형 PLC 프로그램 제어 시스템, 고효율은 대규모 생산 기업에 적합한 고속 충진 장비의 정확성을 보장합니다. 실제 상황에 따라 소량 자동 생산을 구성할 수 있습니다.

Our service:Pre-sale: Accept your inquiries and organize special technical seminars to discuss customer equipment requirements. Provide you with a detailed "equipment plan", including:1. Equipment samples;2. The latest technology and technology of related equipment at home and abroad, and the comparison of the advantages and disadvantages of products of related manufacturers;3. GMP process design, plant water and electricity layout;4. Process design of mechanical equipment;5. Related product configuration, spare parts, packaging and after-sales service;6. Determine the equipment and quote item by item.On sale:1. Keep in touch with you at all times, invite customers to visit the company, and supervise production equipment;2. Prepare the equipment manual, file card and tracking card and other related software, and accept your acceptance at any time;3. Regularly report the production progress of the equipment to the customer.After-sales (operate according to the international standard after-sales service)1. One-year warranty, lifetime service, 24-hour after-sales service website, hotline and fax will be opened for you, and domestic customers will basically arrive at the designated location within 24-72 hours;2. The spare parts inventory is fully stocked for a long time, and the wearing parts, consumable parts and important accessories are guaranteed to respond to customers in the first time;3. Regularly return visits to each customer, once a year, and record the equipment file records.Our company's advantages: 1. The practicability of the equipment: The single machine designed and manufactured by Shouda Company has reliable quality, long service life, low failure rate and convenient maintenance. It can run for more than three to five years without failure under normal use. 2. The operability of the equipment: It is easy to operate, easy to learn and master, suitable for people with different educational levels. At the same time, the equipment is highly standardized and has a strong matching ability, which can easily and quickly replace various parts and components of different specifications. 3. Appearance of the equipment: The appearance design of the equipment is beautiful and generous, in line with ergonomic principles. No matter in terms of material, shape, color, or size ratio, we strive to be more humanized design, so that the appearance and internal quality of the equipment and mechanical performance. , achieve the most perfect unity. 4. Advanced equipment:A. The equipment realizes automatic unmanned operation from automatic bottle unscrambling, bottle washing, filling, sealing, capping, labeling, unpacking, packing, box packaging and other processes.B. Successfully solve the instant foaming, dripping and filling accuracy of filling.C. Successfully solve bottle mouth small-diameter filling and adopt vacuum filling method.D. Successfully developed leading technology in the industry HCF-134A filling machine.E. Adopt import high-quality filling pump.F. The magnetic capping method is adopted, which does not damage the cap and does not loosen.G. Successfully solve the problems of bottle feeding and out of the bottle, broken bottles and bottle pouring of special-shaped bottles.

이전: 캡 라벨링 라인이 있는 고품질 자동 액체 오일 크림 병 충전 기계

다음: 고정밀 0.5-5L 엔진 오일, 브레이크 오일, 모터 오일, 휘발유, 부동액, 윤활유, 병 충전, 캡핑 기계, 충전 기계

당사 연락처